Exploring Different Types of Commercial Roofing: Flat Roof Systems In Baltimore, MD, and Beyond

July 9, 2025

For any business owner or property manager in Baltimore and its surrounding counties, your commercial roof is more than just a cover; it’s a critical asset protecting your entire operation. From inventory and equipment to employees and customers, a reliable roof safeguards your investment and ensures business continuity. However, with numerous options available, choosing between the different flat roof systems for Baltimore, MD, businesses can feel overwhelming.

At Baltimore Roofing & Remodeling, we understand that selecting a commercial roofing system demands careful consideration of factors like upfront cost, long-term durability, energy efficiency, maintenance needs, and specific building requirements. This guide will delve into the most common types of commercial roofing systems – specifically focusing on TPO, EPDM, and Modified Bitumen – helping you understand their unique characteristics, benefits, and considerations to determine which solution best suits your business’s needs.

Understanding Flat and Low-Slope Roof Systems: TPO, EPDM, and Modified Bitumen

Flat and low-slope roofs cover the commercial landscape extensively, offering efficient use of rooftop space and often more cost-effective installation compared to steeply pitched systems. These designs simplify the integration of HVAC units, skylights, and solar panels. Within this prevalent category, single-ply membranes and advanced asphaltic systems have emerged as popular choices due to their inherent flexibility, lightweight nature, and robust performance characteristics. These systems provide a continuous, seamless (or near-seamless) barrier over large areas, making them highly effective for waterproofing vast commercial surfaces.

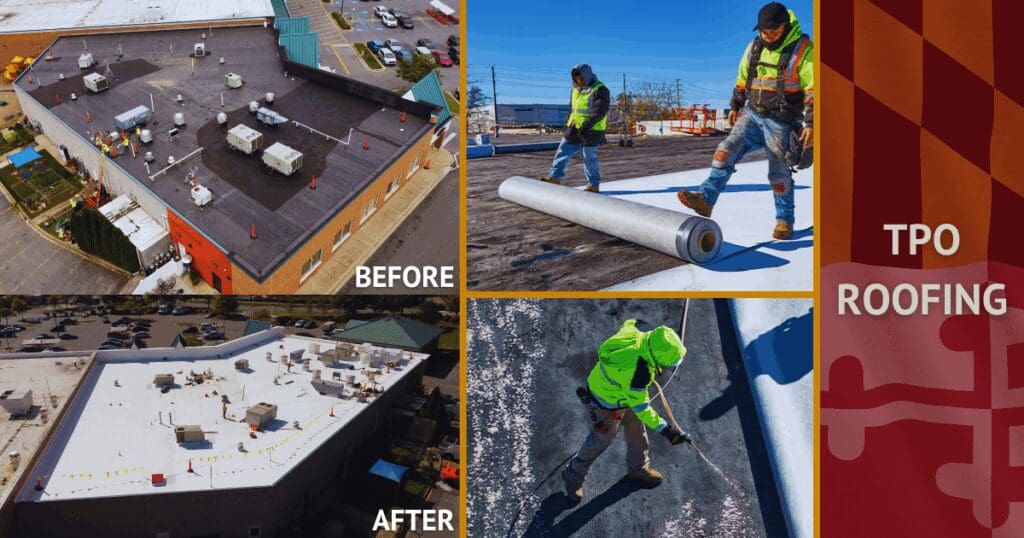

TPO Roofing

Thermoplastic Polyolefin (TPO) roofing has rapidly become one of the most popular choices for commercial flat roof systems Baltimore, MD, businesses choose for their properties. Manufacturers produce TPO as a single-ply membrane material, and the industry celebrates it for its strong performance characteristics, including excellent flexibility, durability, and cost-effectiveness. Its composition makes it a versatile solution for a wide array of commercial and industrial applications across various climates.

Key TPO Roofing Benefits and Lifespan:

- Superb Energy Efficiency: Manufacturers typically produce TPO membranes in white or other light colors, which offer outstanding solar reflectivity. This high emissivity means the roof reflects a significant portion of the sun’s UV rays and infrared radiation away from the building, rather than absorbing them as heat. During Baltimore’s notoriously warm and humid summers, this translates directly into a cooler building interior. Businesses often experience substantial reductions in their air conditioning usage and, consequently, significant savings on their energy bills, contributing to a greener operational footprint and potentially earning energy-efficiency tax credits. This “cool roof” effect also helps to mitigate the urban heat island phenomenon in urbanized areas.

- Remarkable Durability and Lifespan: TPO roofing systems generally offer a strong lifespan, typically ranging from 15 to 30 years, depending on the membrane thickness, quality of installation, and ongoing maintenance. Manufacturers engineer TPO to resist common environmental stressors. It demonstrates strong resistance to tears, punctures from dropped tools or foot traffic, and the accumulation of dirt and grime, maintaining its aesthetic appeal and performance over time. Its inherent flexibility also allows it to accommodate natural building movement and the significant temperature fluctuations experienced across Maryland’s seasons without cracking, splitting, or becoming brittle. This robust nature, coupled with resistance to chemical exposure and harsh UV radiation, significantly contributes to a strong return on investment over its lifecycle, minimizing the need for frequent interventions.

- Efficient and Reliable Installation: Baltimore Roofing & Remodeling typically installs TPO using a hot-air welding process for all seams. This method creates a permanent, monolithic bond at the molecular level, which is often stronger than the membrane itself, ensuring a truly watertight seal. This efficient installation process, especially compared to multi-layer systems like Built-Up Roofing, can lead to quicker project completion times, minimizing disruption to business operations. Installers can secure the membrane in several ways: fully adhering it to the substrate, mechanically fastening it with plates and fasteners, or ballasting it with gravel, offering flexibility based on building design and wind uplift requirements.

- Favorable Cost-Effectiveness: When evaluating commercial roofing options, TPO offers a highly competitive price point. Its balance of reasonable initial TPO roofing costs with long-term performance benefits, including energy savings, durability, and a lifespan often exceeding two decades, presents an attractive value proposition for many businesses. It delivers a superior performance-to-cost ratio, making it a smart, long-term investment for diverse commercial properties seeking to manage operational expenses effectively.

While TPO roofing systems are generally robust and tough, understanding specific flat roof repairs Baltimore, MD, businesses might encounter with TPO is crucial for comprehensive maintenance. Common issues include localized punctures from dropped tools or sharp debris, minor seam issues over many years (though less common with proper welding), or isolated damage from severe weather like high winds. Experienced commercial roofers typically patch these effectively with compatible TPO materials using the same heat-welding techniques, ensuring the repair seamlessly integrates with the existing membrane and maintains the roof’s waterproofing integrity. Regular inspections help identify these minor issues before they escalate into more significant problems, helping to maximize the TPO roofing lifespan.

EPDM Roofing

Ethylene Propylene Diene Monomer (EPDM) roofing, colloquially known as “rubber roofing,” is a high-performance synthetic rubber membrane. It stands widely recognized for its legendary durability, remarkable resilience, and a very long roofing lifespan. EPDM has established itself as a reliable and trusted choice for commercial properties for over half a century, proving its mettle in diverse climates across North America. Its simple chemical structure and inherent flexibility contribute significantly to its longevity.

Key EPDM Roofing Benefits and Lifespan:

- Unparalleled Weather Resistance: EPDM demonstrates resilience across a spectrum of weather conditions. It handles extreme temperature fluctuations, from the intense heat of Baltimore summers to the freezing conditions of winter, without becoming brittle or cracking. Its elastic properties allow it to expand and contract with the building’s natural movement and thermal cycles, minimizing stress on the membrane. EPDM also performs robustly against hail storms, providing top-notch impact resistance, which offers significant peace of mind for business owners in storm-prone regions. It resists both standing water and ponding, crucial for flat roofs.

- Noteworthy Longevity and Durability: EPDM holds a strong reputation for its impressive lifespan, often extending from 30 to 50 years, and frequently longer with meticulous installation and consistent, proactive maintenance. Its inherent composition gives it superior resistance to UV degradation, ozone exposure (a common cause of cracking in other materials), and general weathering, making it an ideal material for long-term outdoor use. This resilience against the elements, including harsh temperature fluctuations, significantly contributes to its prolonged service life, making it a truly long-term asset. EPDM does not become brittle in cold weather and maintains its flexibility across extreme temperatures.

- Favorable Cost-Effectiveness Over Time: While initial EPDM roofing costs might appear similar to or slightly more than basic TPO, its extended lifespan significantly translates into a lower lifecycle cost. The reduced frequency of replacement, combined with its minimal long-term maintenance requirements, provides terrific overall value. This makes EPDM a sound long-term investment for businesses focused on sustainability and cost management over decades, demonstrating its true economic benefit beyond the initial outlay.

- Simplified Repair and Maintenance: Should a puncture, tear, or localized damage occur – typically from sharp falling debris or very specific stressors – EPDM systems generally allow for relatively easy and straightforward repairs. Baltimore Roofing & Remodeling typically cleans the damaged area, applies specialized primers, and then adheres new EPDM patches using strong commercial-grade adhesives. This ensures the repair seamlessly integrates and maintains the system’s waterproofing integrity. This ease of repair means minor issues do not compromise the entire roofing system, thereby significantly extending its overall service life.

- Environmental Responsibility: EPDM often includes recycled materials in its manufacturing process, contributing to sustainable building practices and reducing reliance on virgin resources. Furthermore, at the end of its exceptionally long life, EPDM is often fully recyclable, minimizing landfill waste and supporting environmentally conscious construction and demolition practices. This makes it an attractive option for businesses prioritizing green initiatives and corporate responsibility.

- Superior Fire Resistance: EPDM formulations inherently possess good fire-resistant properties, often meeting stringent fire safety standards and providing an added layer of safety for commercial structures, a crucial consideration for any business operation.

When considering flat roof repairs in Baltimore, MD, for EPDM systems, common issues typically involve localized punctures (Ex: from dropped tools or sharp debris), or, less frequently, seam failures if the adhesive application was suboptimal during the original installation. Baltimore Roofing & Remodeling usually diagnoses and repairs both types of issues straightforwardly and effectively, often through patching or re-adhering seams, thereby preserving the roof system’s integrity. Regular maintenance checks play a vital role in identifying these minor issues before they can develop into more significant problems, helping to capitalize on the system’s inherent longevity.

Modified Bitumen (Mod-Bit) Roofing

Manufacturers specifically design Modified Bitumen (Mod-Bit) roofing, a significant evolution of the traditional Built-Up Roofing (BUR) system, for low-slope or flat roofs. Manufacturers reinforce this asphalt-based system with various polymers (either Atactic Polypropylene – APP, or Styrene Butadiene Styrene – SBS) to enhance its flexibility, durability, and overall performance. Mod-Bit effectively combines the proven waterproofing capabilities of asphalt with the advanced properties of modern plastics or rubbers, offering a robust, multi-layered solution for commercial properties.

Key Mod-Bit Roofing Benefits and Lifespan:

- Superior Flexibility and Thermal Shock Resistance: The “modified” aspect refers to the inclusion of polymer modifiers within the asphalt. These polymers imbue the membrane with enhanced elasticity and flexibility, crucial for accommodating significant temperature fluctuations. This allows the Mod-Bit system to expand and contract effectively with thermal cycles – a constant challenge in the Baltimore climate – without cracking, splitting, or compromising its integrity. This adaptability significantly reduces stress on the system and extends its overall lifespan.

- Strong Durability and Lifespan: Mod-Bit systems offer solid durability, typically providing a reliable lifespan ranging from 15 to 25 years, sometimes more with proper maintenance and superior installation. Mod-Bit membranes are inherently robust, offering strong resistance to punctures, tears, and general wear and tear from foot traffic and environmental stressors. The factory-manufactured rolls ensure consistent quality and thickness, providing a uniform, reliable surface. Its multi-layered composition, often including fiberglass or polyester reinforcing mats, creates a formidable and redundant waterproofing barrier that stands up exceptionally well to ponding water and heavy precipitation common in the Baltimore area.

- Versatile and Controlled Application Methods: Installers can apply Mod-Bit using several techniques, offering adaptability to different project requirements and site conditions, each providing a secure bond:

- Torch-Applied: This method involves heating the underside of the membrane with an open flame torch to melt the asphalt, creating a strong, fused bond to the substrate and at the seams. It results in incredibly strong and watertight seams.

- Self-Adhering (SA): These membranes come with a factory-applied adhesive layer, and a removable release film protects it. Installers simply peel off the film and press the membrane into place, making for a cleaner, safer, flame-free installation with strong adhesion.

- Cold-Applied: This method uses liquid, cold-applied adhesives to bond the membrane layers, eliminating the need for torches or excessive heat. This can be advantageous in sensitive environments or where fire restrictions are in place.

- Hot-Applied: Similar to traditional Built-Up Roofing, hot asphalt can bond some Mod-Bit systems, providing excellent adhesion and a dense, integrated system.

- Favorable Cost-Effectiveness: While the initial Mod-Bit roofing costs can vary based on application method and number of plies, Mod-Bit systems offer a compelling balance of cost and performance. Their multi-layered construction provides inherent redundancy and resilience, leading to a reliable lifespan and making them a cost-effective long-term solution, particularly for businesses seeking proven asphaltic waterproofing technology without the extensive labor of a full BUR system.

- Ease of Repair and Maintenance: Should localized damage occur from severe impact, aging, or specific stressors, Mod-Bit systems generally allow for easy and efficient repairs. Trained professionals can typically clean the damaged area, prime it, and then apply new Mod-Bit patches using compatible materials and the appropriate application method (torch, cold adhesive, or self-adhered). This ensures a seamless and watertight repair, extending the integrity of the overall system. Regular inspections and prompt attention to minor issues contribute significantly to the system’s longevity.

- Energy Efficiency Options: Mod-Bit systems can come with granular surfaces in various colors, including highly reflective white or light-colored options. These reflective surfaces can significantly enhance energy efficiency by reflecting solar radiation, thereby reducing cooling loads on the building and contributing to lower energy bills, though generally not to the same extent as dedicated white TPO or PVC membranes. The choice of surfacing also adds to the aesthetic appeal and provides additional UV protection for the underlying asphalt layers.

When considering flat roof repairs in Baltimore, MD, for Mod-Bit systems, common issues often involve blistering (where trapped moisture or air creates bubbles), cracking due to aging or excessive movement, or localized punctures. Baltimore Roofing & Remodeling can typically address these through patching, re-sealing, or applying fluid-applied repair materials, ensuring the repair integrates effectively with the existing multi-layered membrane.

Choosing the Right Commercial Roofing System for Your Business

Selecting the optimal commercial roof system for your property in Baltimore or the surrounding counties involves a comprehensive evaluation of several interconnected factors. A thorough understanding of these elements ensures you make a strategic investment that maximizes protection, minimizes operational costs, and supports your business’s long-term goals.

- Budget Considerations: This involves assessing both the upfront installation and TPO roofing costs (or for EPDM or Mod-Bit) and the long-term lifecycle costs. While a lower initial price might seem attractive, consider maintenance requirements, potential energy savings over decades, and the expected lifespan of the system. A more expensive upfront investment in a highly durable, energy-efficient system can yield significant savings over decades.

- Building Type and Use: The specific function of your commercial building heavily influences the best roofing choice. For instance, a restaurant with grease-laden exhaust might prioritize membranes with hearty chemical resistance. A manufacturing plant with heavy machinery might require a roof system with superior puncture resistance. Warehouses might prioritize maximum longevity and energy efficiency.

- Roof Slope and Design: The inherent design of your building’s roof, particularly its pitch (flat or low-slope), dictates which systems are viable. TPO, EPDM, and Modified Bitumen are all excellent choices for these common commercial roof configurations, but slight nuances in slope requirements can influence the final recommendation.

- Energy Efficiency Goals: For businesses aiming to reduce utility bills, achieve LEED certification, or pursue broader sustainability initiatives, energy efficiency becomes a primary driver. Highly reflective “cool roofs” (like white TPO or specifically coated Mod-Bit) significantly reduce cooling loads. EPDM’s dark surface absorbs heat, but it also comes in white versions and its insulating properties can still contribute to overall energy performance, particularly in heating-dominated climates.

- Climate and Environmental Conditions: Our Baltimore climate, which features hot, humid summers, freezing winters, freeze-thaw cycles, and occasional severe storms (including high winds and hail), demands materials that can withstand these stressors. The chosen system must demonstrate resilience against UV radiation, extreme temperature fluctuations, and moisture penetration specific to this region.

- Desired Lifespan and Warranty: How long do you envision your roof lasting before requiring replacement? This significantly impacts the initial material choice and overall investment strategy. Materials with longer inherent lifespans, such as the impressive EPDM roofing lifespan, justify a higher initial cost through decades of reliable performance. Always inquire about comprehensive manufacturer and workmanship warranties for long-term protection.

- Maintenance Capacity and Requirements: Some roofing systems demand more frequent or specialized maintenance than others. Consider your operational capacity and budget for ongoing upkeep. Low-maintenance options can reduce long-term operational costs and free up valuable resources.

- Aesthetic Preferences and Branding: While often secondary for commercial roofs, the roof’s appearance can contribute to brand image and overall property value for certain businesses. TPO and EPDM offer clean, uniform looks, while Mod-Bit can have a granular finish, offering some textural variety.

Before making any definitive decisions, a professional commercial roof assessment is paramount. Baltimore Roofing & Remodeling will thoroughly inspect your existing roof, meticulously evaluate your building’s specific operational needs and long-term objectives, and provide tailored recommendations based on expert knowledge of material performance and local building codes. They can discuss the nuances of types of commercial roofing systems in detail and help you understand how each performs in a real-world scenario, offering insights into projected TPO roofing costs or other system expenses, and anticipated lifecycles.

Partner with Baltimore Roofing & Remodeling: Your Trusted Commercial Roofing Experts

At Baltimore Roofing & Remodeling, we specialize in comprehensive commercial roofing services across Baltimore and the surrounding counties. Our expertise spans a wide array of commercial systems, from new installations of advanced flat roof systems Baltimore, MD, businesses trust, like TPO, EPDM, and Modified Bitumen, to meticulous flat roof repairs Baltimore, MD, companies rely on. We possess the certifications, experience, and local knowledge dating back to 1885 to deliver lasting, high-performance solutions tailored to your unique business needs.

We take immense pride in helping businesses protect their most valuable assets with high-quality, durable, and energy-efficient roofing solutions. Our commitment extends beyond installation; we aim to be your trusted long-term partner for all commercial roofing needs.

Contact us today for a professional consultation. Let us assess your current roof, discuss your operational goals, and discover which commercial roofing system is the right, strategic investment for your business’s future and continued success.

Leave a Reply Cancel reply

© Copyright 2025 Baltimore Roofing And Remodeling LLC